News Center

Shandong Zhensure New Materials Technology Industry Co., Ltd.

When selecting WPC (Wood Plastic Composite) decking for a project, buyers are often faced with a fundamental choice right from the sta

rt: hollow or solid core profiles. While they may look similar on the surface, this internal structural difference significantly impacts performance, cost, and ideal application areas. At Zhensure, a leading Chinese manufacturer specializing in high-performance WPC solutions for global markets, we believe that understanding this core distinction is key to specifying the perfect material for your needs. This guide will explore the differences between hollow and solid WPC decking to help you make an informed decision.

Understanding the Core Difference: Structure Defines Application

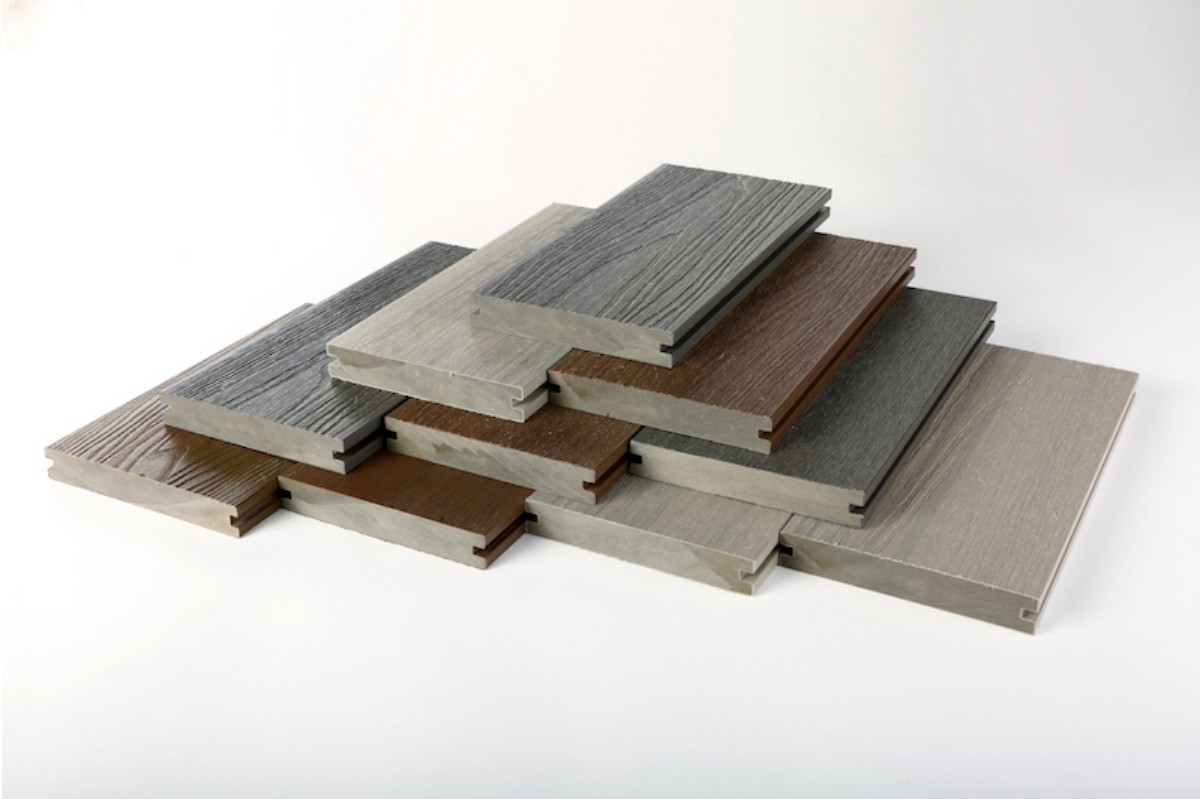

The primary classification of WPC boards lies in their cross-sectional design. Hollow profiles feature a multi-chambered, lightweight structure, while solid profiles are, as the name suggests, completely dense. This simple difference dictates their strengths and best-use scenarios.

The Strength and Premium Performance of Solid WPC Decking

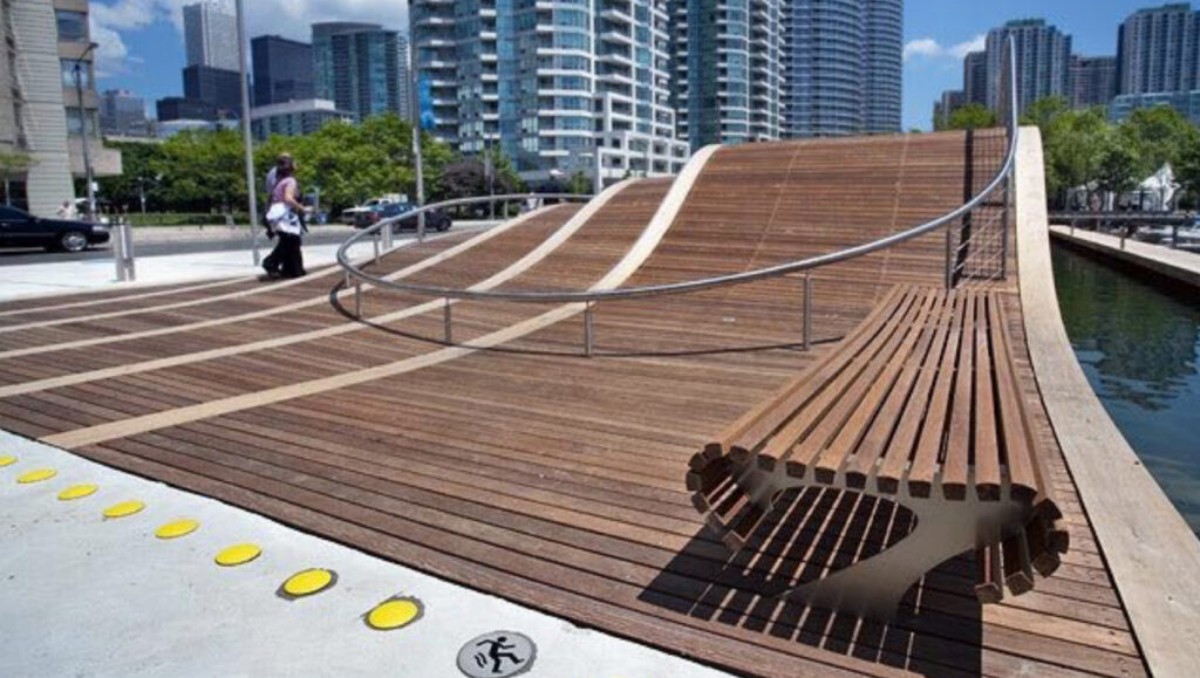

Solid WPC decking is renowned for its exceptional strength and durability. The dense core provides superior load-bearing capacity, making it the ideal choice for high-traffic commercial applications. Its increased density also contributes to enhanced resistance against impacts and extreme weather conditions.

Ideal For: Public parks, boardwalks, commercial plazas, and any area expecting heavy foot traffic or where maximum durability is a priority.

The Versatility and Value of Hollow WPC Decking

Hollow WPC decking offers an excellent balance of strength and affordability. The engineered hollow structure provides remarkable rigidity while reducing material usage, which translates to a lighter weight and more cost-effective solution. It is easier to handle and install, making it a favorite for residential projects.

Ideal For: Private gardens, balconies, patios, and residential terraces where excellent performance is required without exceeding the budget. You can explore our range of versatile profiles on our WPC decking product page.

Choosing the Right Surface: Co-extruded vs. Non Co-extruded

Beyond the core, the surface technology is crucial for longevity. Standard non co-extruded WPC has a realistic wood-grain texture but is more susceptible to surface wear over time. For superior protection, Zhensure recommends co-extruded WPC. This advanced type features a durable polymer cap layer that provides outstanding resistance to moisture, UV rays, stains, and mildew, ensuring the deck retains its beauty for years with minimal maintenance.

Perfect Applications for Your WPC Decking

Choosing the correct profile ensures project success:

Residential Havens: Both hollow and solid WPC are perfect for creating beautiful, low-maintenance outdoor living spaces in homes and villas. For areas around pools, co-extruded solid WPC is highly recommended.

Commercial Spaces: Enhance office building rooftops, hotel terraces, and restaurant courtyards with the robust performance of solid WPC decking.

Public & Coastal Projects: Parks, school grounds, and especially coastal boardwalks benefit immensely from the durability and moisture resistance of high-grade solid WPC materials.

Conclusion

The decision between hollow and solid WPC decking ultimately hinges on the specific demands of your project, balancing factors like budget, expected load, and location. By understanding the distinct advantages of each type, you can confidently select a material that delivers both performance and value. As a trusted factory with extensive export experience, Zhensure is committed to providing importers and distributors with premium-quality WPC solutions tailored to diverse market needs. Partner with us to supply your clients with the ideal decking for every application.

Driven by increasing environmental awareness and stricter market regulations, global demand for sustainable building materials continues to grow.

For importers and distributors sourcing building materials, the long-term appearance of a product is a key factor in customer satisfaction. As a leading wood-plastic composite flooring manufacturer in China, Zhensure recently completed a large-volume delivery of wood-plastic composite flooring to a key customer in Croatia, Europe.

As a leading wood-plastic composite flooring manufacturer in China, zhnesure understands the growing international demand for durable, low-maintenance outdoor solutions. This article explores the key characteristics and advantages of wood-plastic composite flooring (WPC) to help importers, distributors, and wholesalers understand why it is the ideal choice for their markets.

We are delighted to share a recent success story of our wood-plastic composite flooring being shipped to a valued customer in Croatia, Europe. This project highlights not only the trust our international clients place in Zhensure’s products but also our commitment to prompt and reliable delivery—a key factor in building lasting partnerships across continents.

When it comes to enhancing your outdoor living area, selecting the right materials for your WPC wall panel and decking is crucial.